In addition to personally handcrafting each Soyuz microphone, our team is also responsible for building its complimentary oak carrying case. Watch our new video to see the woodworking process in near-real-time and continue below for more details on each step.

Soyuz utilizes dry unedged oak boards for our handmade cases.

We prefer oak because of its expressive texture, hardness and durability. Oak is tolerant to moisture and extremely resistant to decay over long periods of time.

When selecting each piece of wood, we make sure there is a minimum amount of natural spots and avoid any boards that are yellowing (a sign of rotting wood).

Each wood billet is traced to the necessary length for its place in our case. These parts are then cut to size with a bit of reserved space for further jointing and cutting.

Next, our craftsmen use a jointer to ensure each piece of wood has a perfectly flat surface. Each billet is then cut further using a saw.

Attention to detail is extremely critical here, as any error in sizing means throwing out a perfectly good wood billet.

Over on the ribbon saw, each piece of wood is cut into two different pieces.

It’s at this stage that our team is able to get a better understanding of what’s going on inside the wood. If any defects are uncovered (yellow spots, cracks, swirls), the piece will be rejected.

The boards are passed through the thickness gauge to make sure they are the necessary thickness and that all sides are parallel.

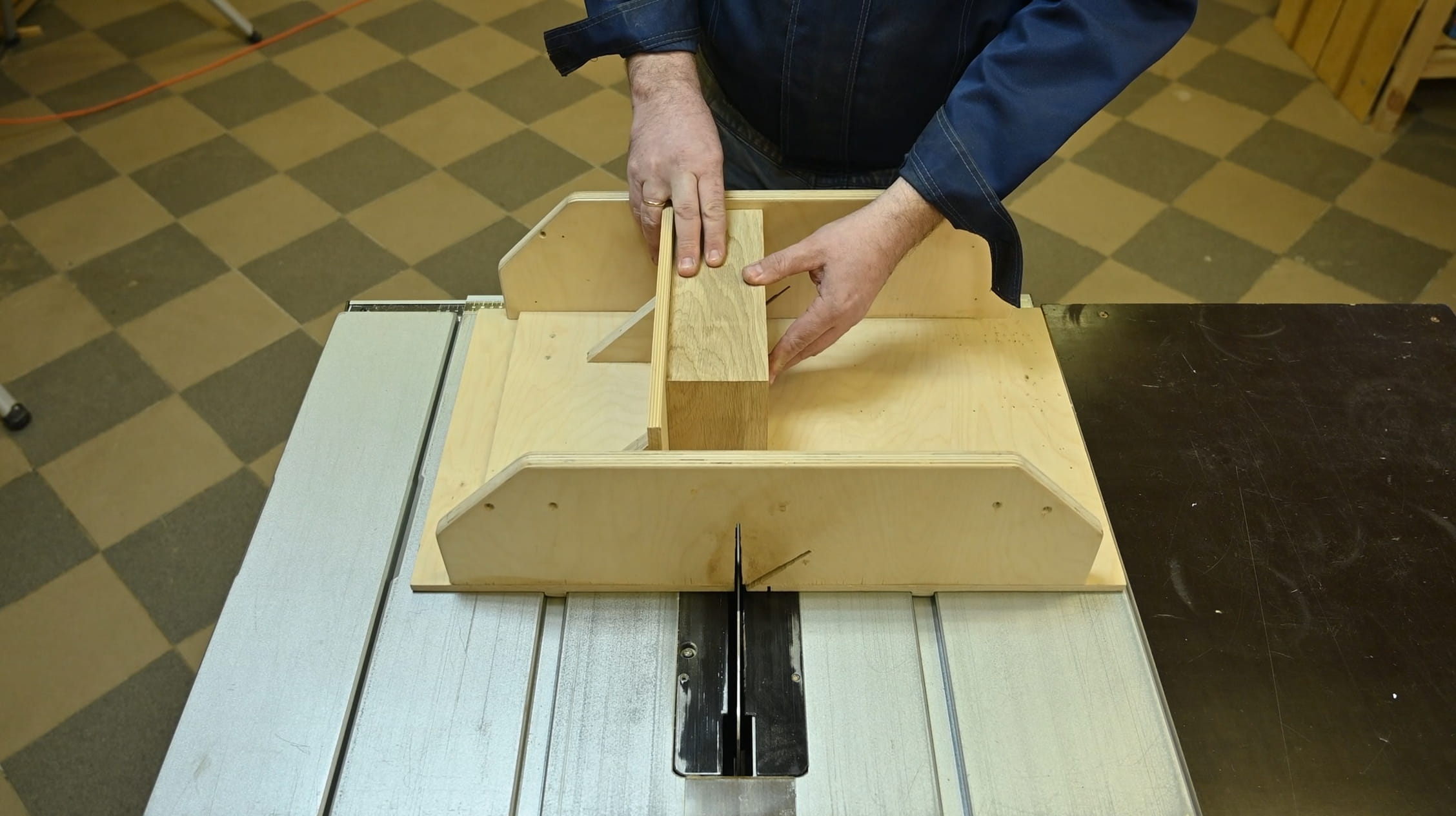

The next step of the process is to head to the table saw and cut each piece of wood at a 45-degree angle. These angles will help the box take shape during the gluing process.

This stage is critical to the accuracy of building the case, as each cut ensures the end product has the proper geometric shape.

On the milling table, a groove cutter is used for what will become the box’s lid and bottom. This will make the box a more stable structure and keep the wood from curving in high and low moisture conditions.

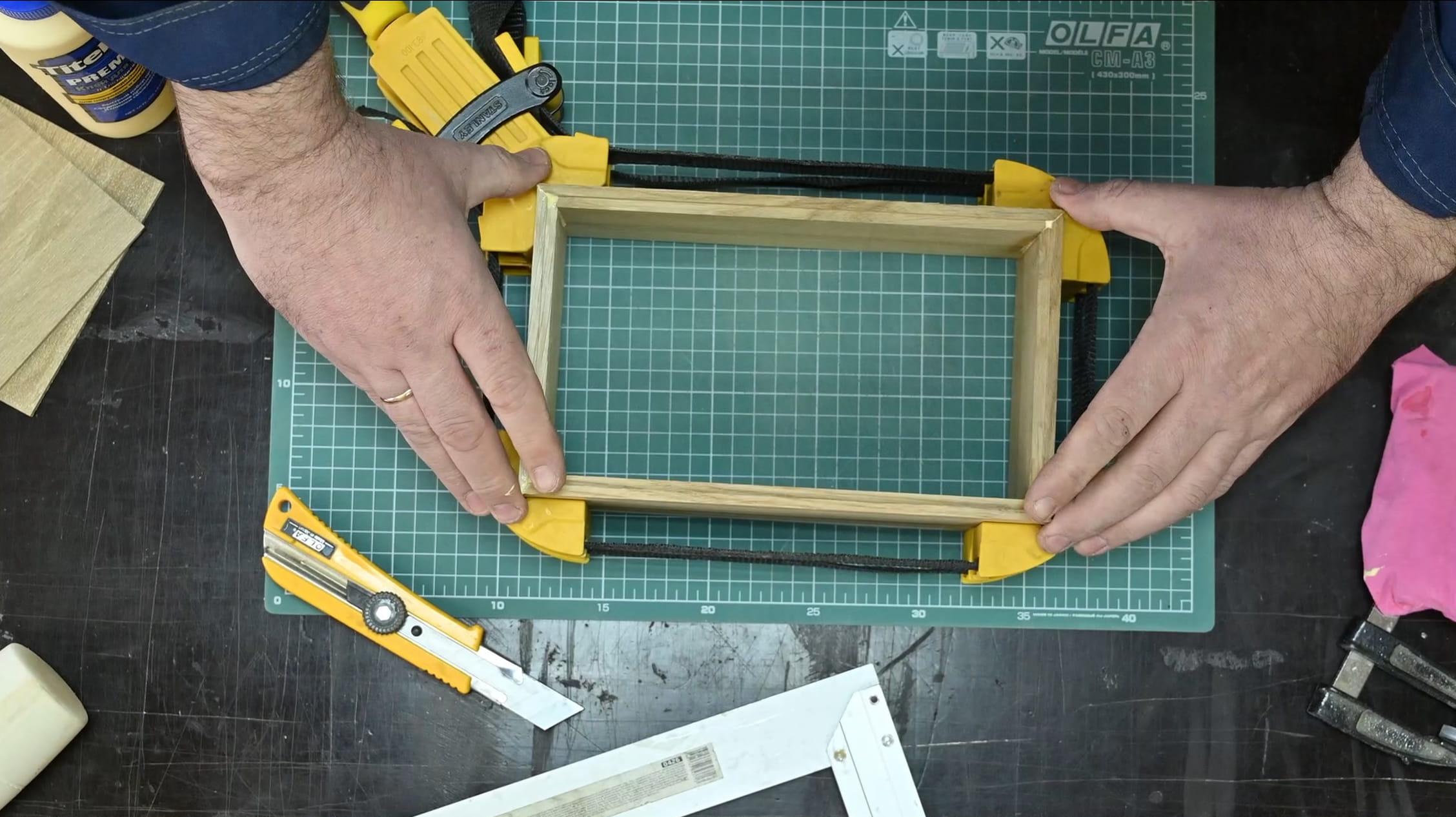

The walls, partitions, lid and bottom of the box are then glued together and held in place by using a clamp. After applying the glue, our team acts fast, as assembly needs to be carried out carefully and quickly before the glue dries.

After the glue has dried, a grinder is used to remove all irregularities and excess glue from the box.

Soyuz team members once again use an oak product (this time a veneer) to give the box a beautiful finished look.

Once the veneer has been glued onto the box, excess material is cut off using a utility knife. The box is then gently grinded to make sure it has a seamless construction.

With the box fully assembled, it’s time to cut it into two pieces, the lid and the bottom.

One wrong cut ensures that the process has to be started over again, so this is one of the most important steps in building our cases.

The separated lid and bottom are then grinded with sandpaper to make sure that both surfaces are flush with each other when the box is closed.

Each of our handmade cases has magnets in the lid and bottom for the perfect seal.

Installing the magnets and hinges of the box is one of the last steps in our process.

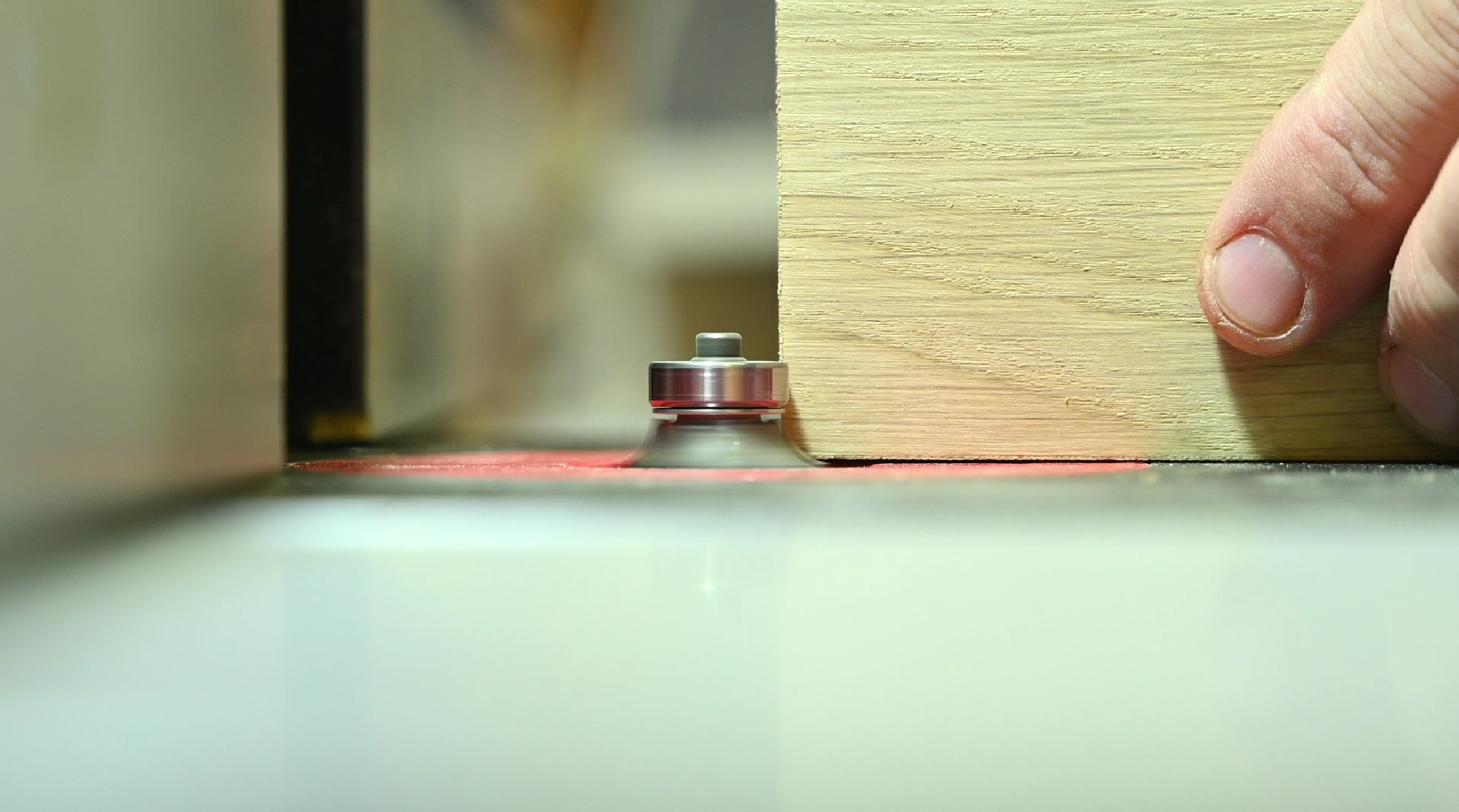

With magnets and loops in place, our craftsmen head back to the milling table to take off the box’s sharp corners with an overrun bearing. The box is once again examined for any flaws or defects.

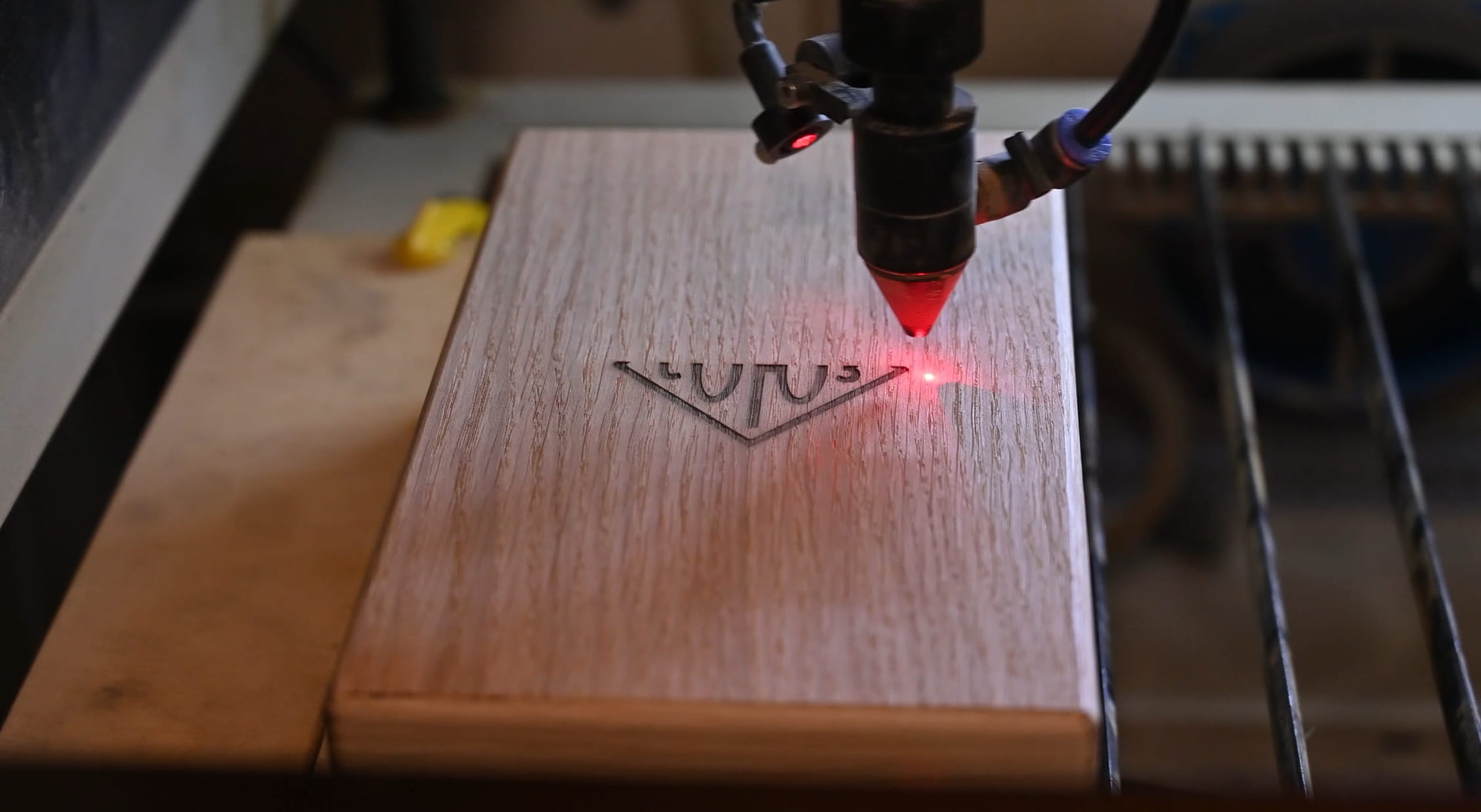

The box is now passed through our laser engraving station. Soyuz uses a carbon dioxide laser in the workshop. which helps to make a precise high-quality engraving on the wooden veneer.

The last step of our process is to treat the completed box with oil. Soyuz uses oil as it’s more environmentally friendly and safer to handle than most other lacquers. It also has a more natural look that shows off the pattern and texture of the wood, while protecting from moisture and other elements.

And with that… Our Soyuz craftsmen have completed building one of our custom microphone cases.